LEAN MANUFACTURING AT ITS BEST!

In order to maintain our competitiveness to the highest level and provide the best value to our customers, Innergy tech had spent a significant amount of time and money in the re-engineering of its manufacturing and business processes which led us in 2003 to the implementation of the latest lean manufacturing techniques.

The main objectives of the lean manufacturing techniques are to remove from the manufacturing processes any operation that does not bring added value to our products and to ensure FLEXIBILITY and RELIABILITY in delivering our products as per customer needs.

These non-added value elements can be:

- Wasted time

- Manufacturing process wastes

- Unnecessary inventory

- Inefficient manufacturing processes

- Production far in advance

- Long lead times

- Inefficient business processes

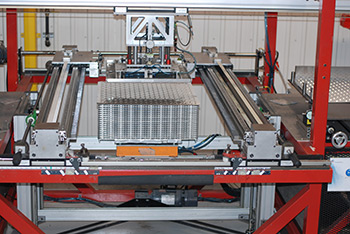

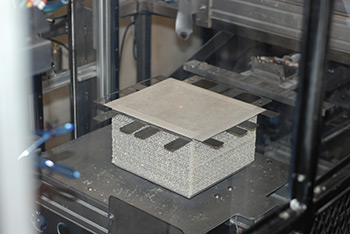

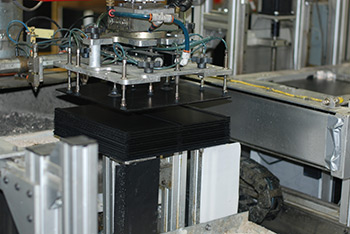

Consequently, Innergy tech manufacturing facility has been organized by production cell for each product line and respecting the concept of "one piece flow" giving to our customer the maximum flexibility that can exist on the market.

In order to support our flexible manufacturing facility, we have developed our supply chain by using the latest KANBAN Techniques (procurement concept developed by Toyota) insuring a smooth reordering process without keeping too much of an inventory and is monitored by an ERP manufacturing system.

A flexible manufacturer can bring a lot of value and RELIABILITY to your own supply chain, just ask us how we can help you out in improving your competitiveness...